+33 (0)5 24 54 52 00

Rue François Mitterrand,

Institut d'Optique d'Aquitaine

33400 Talence

France

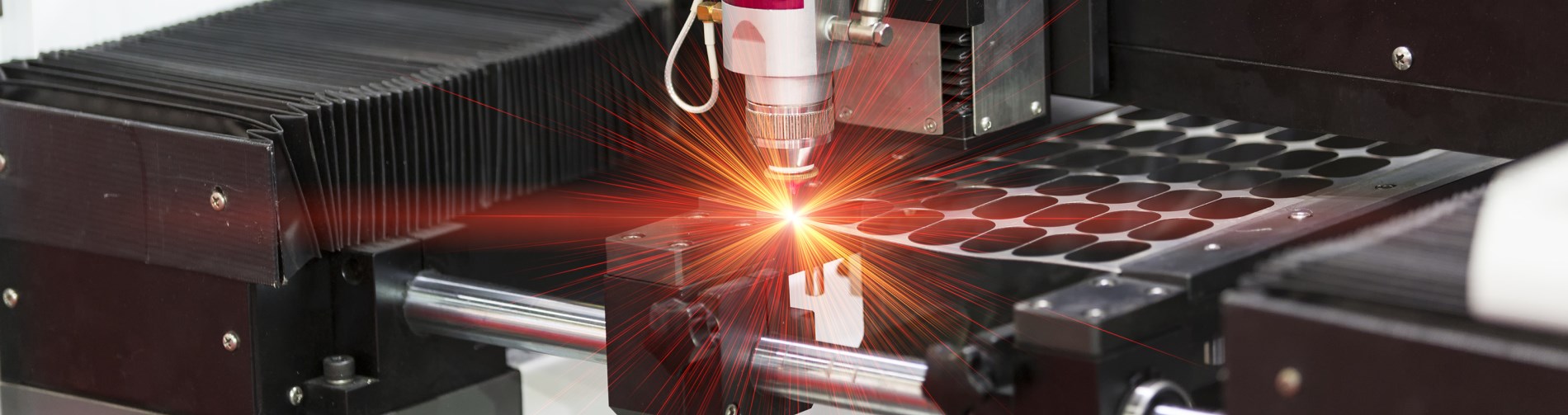

ALPhANOV is a leading player in the field of laser processes.

From the development of innovative processes to the design of custom R&D systems, ALPhANOV supports its clients at every stage of their industrial workflow.

Thanks to its expertise and technological capabilities, ALPhANOV offers a comprehensive range of laser process services, covering the entire industrial cycle:

- Studies and analyses based on in-depth expertise in laser–matter interactions

- Experimental validation supported by a wide range of laser sources and monitoring and measurement instruments

- Development of reliable and robust processes, integrating repeatability requirements and associated procedures

- Prototype manufacturing and small-series subcontracting

- Support for the integration of laser processes into industrial environments

- Training of users in laser processes and safety rules

ALPhANOV develops and secures advanced laser processes, notably beam shaping, surface engineering, transparent material machining, drilling, cutting, marking, engraving, and selective ablation.

These processes are applied to a wide variety of materials and enable high-precision machining. The use of femtosecond lasers ensures fine control of laser–matter interactions, high repeatability, and a drastic reduction of the heat-affected zone, meeting the requirements of industrial environments and high value-added applications.

Special machines:

ALPhANOV’s expertise covers the entire value chain, from design to manufacturing of sub-assemblies and complete systems dedicated to laser machining.

ALPhANOV designs and develops its own laser machining and micromachining benches and offers the production of tailor-made systems perfectly suited to the application-specific and industrial requirements of its clients.

The ALPhANOV teams design machines that are process-centric, ensuring design validation and final acceptance according to strict specifications. Each project is managed through a controlled stage-gating process, aligned with ALPhANOV’s quality system, guaranteeing traceability, risk management, and compliance with customer needs, supported by regular exchanges throughout the development.

The agility and expertise of the teams also allow systems to evolve throughout their entire lifecycle, whether involving the integration of new laser sources, performance optimization, or equipment automation, ensuring long-term support for industrial and technological developments.